Precision manufacturing for high-performance components

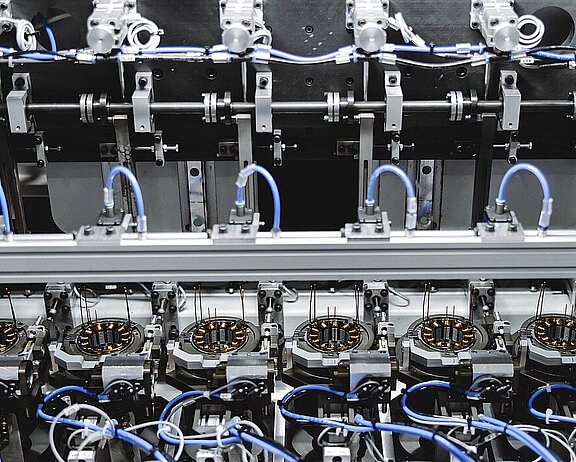

The production of solenoid coils and systems is traditionally one of Hechinger's absolute core competencies and strengths. We manufacture coils and several million coil systems with a wide range of applications according to your requirements.

We use winding technology to produce complex components - we use needle winding technology and linear winding technology for this.

Both processes allow us to produce highly resilient, customer-specific composite materials with optimized material orientation, which are used in various areas.

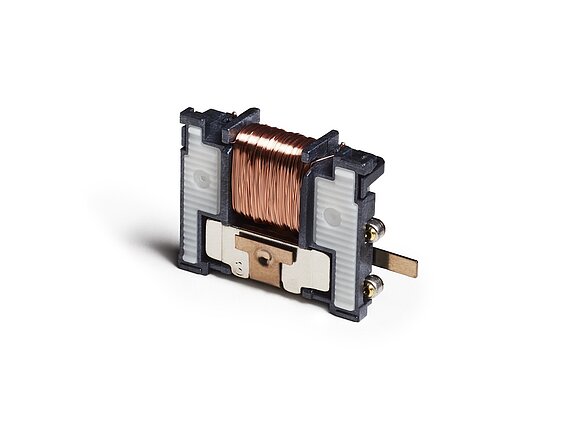

Linear winding technology

Linear winding technology enables optimum material utilization and precise winding of elongated components. It is particularly suitable for applications in drive technology, sensor technology and industrial mechatronics, where uniform and elongated coil structures are required. In contrast to needle winding technology, winding takes place in a stretched movement, which is particularly advantageous for:

- Long, stretched coil shapes

- Coils with a uniform winding arrangement

- Applications with linear winding requirements

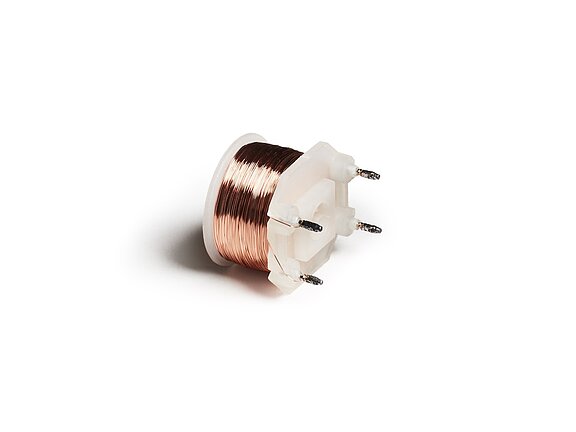

Needle winding technology

We use needle winding technology to produce complex three-dimensional coil geometries, which are primarily used for components in drive technology, sensor technology and mechatronic systems with high precision requirements. Compared to linear winding technology, needle winding technology offers better possibilities for:

- Compact, circular coil geometries

- Highest density of windings in minimal installation spaces

- Precise winding arrangement for three-dimensional structures

Product & solution examples

100 million

Winding parts per year

0.05-2 mm

Wire diameter

>1.000 t

Copper per year

Want to make things work?

Would you like to work with us or do you have questions about our company? With pleasure. Simply get in touch with us.